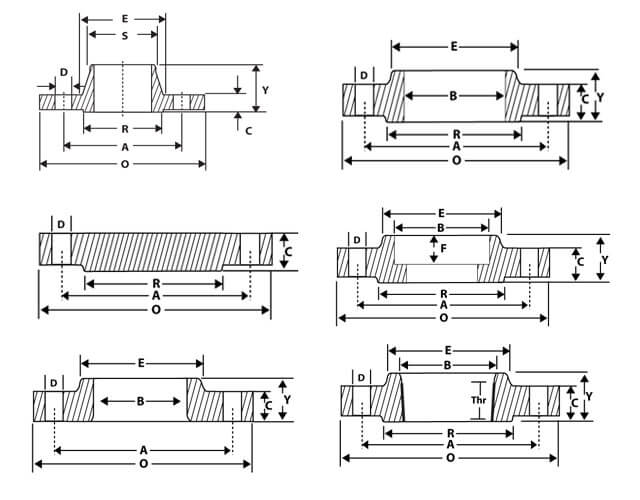

The lap joint flange derived it name lap joint as it is to be joint with a joint stub end. The flange has curved radius at its bore to accommodate a lap joint stub. A lap joint flange is similar in some ways as slip-on flange as a stub end is slipped on the flange having slightly larger radius then the stub end joint. lap joint stub and flange are joint together to make a assembly. Thus lap joint flange allows easy dismantling of system assembly. We manufacture lap joint flange in different sizes and standards.

| DIMENSIONS TOLERANCES OF FLANGES (in mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Welding neck | Threaded, Slip on lap joint, Socket welding and blind |

||||||||

| * | outside diameter | O.D. 600 if smaller | + 1.6

_ |

||||||

| O.D. over 600 | + 3.1

_ |

* | outside diameter | O.D. 600 or smaller | + 1.6

_ |

||||

| O.D. over 600 | + 3.1

_ |

||||||||

| 250 and smaller | + 0.7

_ |

inside diameter | threaded : to stand gauge limit | ||||||

| inside diameter | 12 though 450 | + 1.6

_ |

(bore) | slop on .lap joint : socket-welding | |||||

| (bore) | 500 and larger | + 3.1 |

- 1.6 |

250 and smaller | + 0.7 |

- 0.0 |

|||

| 300 and larger | + 1.6 |

- 0.0 |

|||||||

| 1.6 raised face | + 0.4

_ |

threaded | |||||||

| diameter of | 6.3 raised face tounge & | diameter of | 250 and smaller | + 0.7 |

- 0.0 |

||||

| contact face | groove male and female | + 0.4

_ |

counter bore | 300 and larger | + 1.6 |

- 0.0 |

|||

| * | outside diameter | 300 and smaller | + 2.3 |

- 1.6 |

|||||

| * | diameter of hub | 125 and smaller | + 2.2 |

- 0.7 |

of hub | 350 and larger | + 3.1

_ |

||

| at point of weding | 150 and larger | + 4.0 |

- 0.7 |

||||||

| diameter of | 1.6 raised face | + 0.7

_ |

|||||||

| contact face | 6.3 raised fact tongue & grooved | ||||||||

| Thickness | 450 and smaller | + 3.1 |

- 0.0 |

male & female | + 0.4

_ |

||||

| 500 and larger | + 4.7 |

- 0.0 |

|||||||

| Thickness | 450 and smaller | + 3.1 |

- 0.0 |

||||||

| length through | 250 and smaller | + 1.6

_ |

hub | 500 and larger | + 4.7 |

- 0.0 |

|||

| hub | 300 and larger | + 3.1

_ |

|||||||

| * | length through | 450 and smaller | + 3.0 |

- 1.6 |

|||||

| hub | 500 and larger | + 4.8 |

- 1.6 |

||||||

| bolt circle | 600 and smaller | + 0.7

_ |

|||||||

| 600 and larger | + 1.6

_ |

bolt circle | + 1.6

_ |

||||||

| drilling | bolt hole spacing | + 0.7

_ |

|||||||

| drilling | bolt hole spacing | + 0.7

_ |

|||||||

| eccenticity with respect | eccenticity with respect | ||||||||

| to bore | 0.70 max | to bore | 0.70 max | ||||||